Clyde Bergemann Soot Blowers

Industrial Boilers America is a leading soot blower manufacturer providing premium-grade Clyde Bergemann soot blower replacements. We offer a range of premium-grade industrial soot blowers tailored to meet the specific needs of your application, designed to minimize thermal heat loss and reduce maintenance costs.

Trusted by

Clyde Bergemann Soot Blowers

As a leading supplier of Clyde Bergemann soot blower replacements, Industrial Boilers America offers high-quality, U.S.-made products that are stronger, more durable, and more cost-effective. We provide exact-fit soot blowers and part replacements for Clyde Bergemann systems, or we can engineer superior alternatives tailored to your application. Our team of experienced engineers can reverse-engineer or custom-design industrial soot blowers and complete soot blowing systems, all at competitive prices and with reliable delivery timelines. Whether you’re looking for an exact Clyde Bergemann replacement or a higher performance upgrade, Industrial Boilers America has you covered. We work closely with our customers to design solutions that reduce costs and accelerate return on investment.

Global Partners

We’re able to adapt to your needs through our vast experience and global relationships. When you want to grow, we will show the way.

High Quality

Industrial Boilers America provides you with the best Clyde Bergemann soot blower replacements out there. The steel is thicker, the material is thicker, and everything lasts longer.

Relationship Focused

We are focused on relationships over profit. Happy customers are our main focus at Industrial Boilers America.

LOW COST SOLUTIONS

Working with us means lower costs, which allows you to reinvest in yourself and expand your impact on the planet.

What is a Clyde Bergemann Soot Blower?

A Clyde Bergemann soot blower is a high-quality industrial device manufactured by Clyde Industries. It’s a critical piece of auxiliary equipment designed to remove soot buildup from the internal surfaces of industrial boilers, helping ensure smooth, safe, and efficient operation.

As your boiler runs, the combustion process produces soot, a carbon-based byproduct that accumulates over time on boiler walls and heat transfer surfaces. This buildup can reduce efficiency, increase fuel consumption, and cause potential damage or unplanned downtime.

Clyde Bergemann soot blowers use high-pressure steam or compressed air to dislodge soot from these surfaces. Steam is often preferred due to its lower cost compared to the capital investment needed for compressors, motors, and air control systems. Once removed, the soot is carried away by flue gas and directed to a dust collector or expelled through the smokestack.

By routinely cleaning boiler surfaces, Clyde Bergemann soot blowers help maintain optimal thermal performance and extend equipment life, making them essential to a wide range of industrial applications.

OUR CAPABILITIES

Types of Soot Blowers

We provide Clyde Bergemann soot blowers or high-quality replacements for boiler cleaning applications, including wall blowers, retractable soot blowers, air heaters, and other specialty cleaning functions.

There are various types of Clyde Bergemann soot blowers used in different areas of an industrial boiler, each with its own benefits.

Wall Soot Blower

A wall soot blower is one of the most common and simple forms of soot blowers. A wall soot blower is a small piece of industrial equipment that connects to the outside of the industrial boiler. A short nozzle enters the boiler and expels hot steam or compressed air to clean the surrounding area. The nozzle then retracts when not in use, making the wall soot blower ideal for regions that reach higher temperatures.

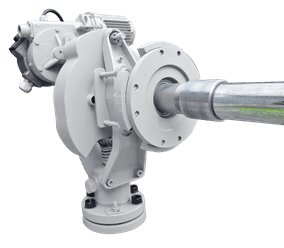

Retractable Soot Blowers LRSB

A long retractable LRSB soot blower is an industrial device that extends a long nozzle into the industrial boiler. The LRSB starts at the beginning of the industrial boiler and slowly moves through it, rotating 360 degrees to remove soot from all surfaces. Once the entire cleaning is complete, the lance withdraws, which is perfect for high-temperature areas. The biggest advantage of the long retractable soot blower is that a single device can clean a much larger area than a simple wall blower.

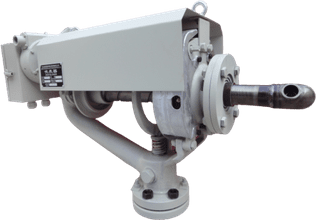

Air Heater Soot Blowers

Air heater soot blowers are specifically designed to clean the air heaters of your industrial boiler. Over time, moisture accumulates at the cold end of the air heater when the flue gas temperature falls below the condensation temperature. This moisture ends up mixing with soot and other byproducts, which creates a fine-grain deposit. Air heater soot blowers are added on the cold end of your air heater and can consist of retractable blowers or blowers with nozzles installed on swinging arms. This device will move across the face of your industrial air heater, while a swinging arm will move in an arc across the face of the heat transfer surface, cleaning a much larger area.

Fixed Rotary Soot Blowers

A fixed rotary soot blower is attached to the industrial boiler, and unlike the other soot blowers, this does not retract like the others listed above. Instead, in the rotary soot blower, the blowing tube/element of the blower remains in the industrial boiler at all times. This tube is often equipped with multiple nozzles and rotates to clean a large portion of the industrial boiler. Since this soot blower doesn’t retract, the blowers cannot be used in the high-temperature areas of your boiler. Rotary soot blowers are ideal for use in the superheater, economizer, and air heater.

TESTIMONIALS

SEE WHAT OUR CUSTOMERS ARE SAYING

Benefits of Clyde Bergemann Soot Blowers

- Improves operational efficiency

- Industrial Boilers last longer

- Keeps boiler running smoothly, safely, and efficiently

- Reduces the cost of thermal heat loss

- Reduces the need for maintenance

Industrial Boilers America has over 20+ years of experience designing, deploying, and manufacturing industrial equipment for industrial boilers and power plants. We will work with you to address your challenges and develop a solution tailored to your specific application and needs. We want you to be worry-free so that you can reinvest your time and capital into your company and community, and together, we can make a positive impact on global sustainability.

Better Solutions

REQUEST A QUOTE

Better Solutions

REQUEST A QUOTE

frequently asked questions

A Clyde Bergemann soot blower is an industrial cleaning device used to remove soot and ash deposits inside boilers. These blowers use steam or compressed air to clean heat-exchange surfaces, maintaining boiler efficiency, safety, and performance.

The blowers insert a lance or nozzle into the boiler, then emit high-pressure steam or air to dislodge soot build-up. The removed soot is carried away by flue gas or collected by dust-handling systems.

Some common types include:

- Retractable soot blowers (long lance types) for deep cleaning

- Part-retractable blowers for partial insertion and impact in mid-temperature zones

- Wall / fixed / stationary blowers for furnace wall areas

- Rake blowers for finned surfaces and economizers

- Oscillating blowers for sweeping movement in less aggressive zones

- SMART / control‑enabled blowers with variable helix, oscillation, and pressure control modes for optimized, on-demand cleaning

Consider:

- The boiler’s design section (e.g. superheater, economizer, air heater)

- Fouling severity, operating temperature, and flue gas conditions

- Available cleaning medium (steam, air) and pressure supply

- Accessibility, space constraints, and mounting needs

- Whether you’d benefit from SMART control / variable cleaning modes

- Maintenance preferences and spare parts availability

- Our engineering team can help you select or design the optimal soot blower solution for your system.

Clyde Bergemann and Diamond Power are both high-quality sooting / boiler cleaning brands. The differences lie in design philosophies, control options, parts ecosystems, and preferred applications. If you need help evaluating which brand or model best fits your boiler, we can assist in technical comparisons and recommendations.