DIAMOND POWER SOOT BLOWERS

Industrial Boilers America is a leading manufacturer of soot blowers, providing premium-grade Diamond Power® soot blowers and replacement parts. We offer a range of premium-grade industrial soot blowers tailored to meet the specific needs of your application, designed to minimize thermal heat loss and reduce maintenance costs.

Trusted by

Diamond Power Soot Blowers

As a leading supplier of Diamond Power soot blowers, Industrial Boilers America ensures that our replacements are proudly made in the United States. Our products boast enhanced strength and durability. Whether you need precise soot blowers or part replacements for Diamond Power, we’ve got you covered. Not only are our products superior, but they also offer long-term cost savings. Our team of engineers is dedicated to providing exact replacements or designing custom industrial soot blowers and systems tailored to your specific needs, all at competitive prices and within timely delivery times. Whether you’re after an exact match or a higher-quality replacement, Industrial Boilers America is here to meet your requirements. We collaborate closely with our customers to find designs that suit their applications, aiming to deliver cost savings that ensure a quicker return on investment.

Global Partners

We’re able to adapt to your needs through our vast experience and global relationships. When you want to grow, we will show the way.

High Quality

Industrial Boilers America provides you with the best Diamond Power® soot blower replacements out there. The steel is thicker, the material is thicker, and everything lasts longer.

Relationship Focused

We are focused on relationships over profit. Happy customers are our main focus at Industrial Boilers America.

LOW COST SOLUTIONS

Working with us means lower costs, which allows you to reinvest in yourself and expand your impact on the planet.

What is a Diamond Power Soot Blower?

A Diamond Power soot blower is a high-performance cleaning device manufactured by Babcock & Wilcox (B&W). It is a critical piece of auxiliary equipment used to remove soot buildup inside industrial boilers, helping ensure safe, efficient, and uninterrupted operation.

As industrial boilers run, combustion processes generate byproducts like soot, a fine carbon residue, that accumulates on internal surfaces over time. Without regular cleaning, this buildup can reduce heat transfer efficiency, increase fuel consumption, and lead to potential damage or unplanned downtime.

Diamond Power soot blowers use high-pressure steam or compressed air to dislodge soot from boiler tubes and internal surfaces. Of the two, steam is often preferred due to its lower capital requirements compared to air systems, which require additional compressors, motors, and controls. Once dislodged, the soot is carried away by the flue gas stream and captured in a dust collector or expelled through the smokestack.

By regularly cleaning heat exchange surfaces, Diamond Power soot blowers extend equipment life, maintain system efficiency, and reduce maintenance costs. They’re a wise investment for any industrial operation that relies on consistent boiler performance.

OUR CAPABILITIES

Types of Soot Blowers

We can provide Diamond Power soot blowers or high-quality replacements for boiler cleaning applications, including wall blowers, retractable soot blowers, air heaters, and other specialty cleaning functions.

There are various types of Diamond Power soot blowers used in different areas of an industrial boiler, each with its own benefits.

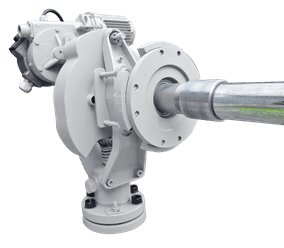

Wall Soot Blower

A wall soot blower is one of the most common and straightforward forms of soot blowers. A wall soot blower is a small piece of industrial equipment that connects to the outside of the industrial boiler. A short nozzle enters the boiler and expels hot steam or compressed air in order to clean the surrounding area. The nozzle then retracts when it’s not being used, which makes the wall soot blower ideal for areas that reach higher temperatures.

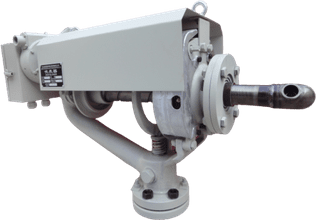

Retractable Soot Blowers LRSB

A long retractable LRSB soot blower is an industrial device that extends a long nozzle into the industrial boiler. The LRSB begins at the start of the industrial boiler and gradually moves through it, rotating 360 degrees to remove soot from all surfaces. Once the entire cleaning is complete, the lance withdraws, which is perfect for high-temperature areas. The most significant advantage of the long retractable soot blower is that a single device can clean a much larger area than a simple wall blower.

Air Heater Soot Blowers

Air heater soot blowers are specifically designed to clean the air heaters of your industrial boiler. Over time, moisture accumulates at the cold end of the air heater when the flue gas temperature falls below the condensation temperature. This moisture ends up mixing with soot and other byproducts, creating a fine-grained deposit. Air heater soot blowers are added on the cold end of your air heater and can consist of retractable blowers or blowers with nozzles installed on swinging arms. This device will move across the face of your industrial air heater, while a swinging arm will move in an arc across the heat transfer surface, cleaning a much larger area.

Fixed Rotary Soot Blowers

A fixed rotary soot blower is attached to the industrial boiler, and unlike the other soot blowers, this does not retract like the others listed above. Instead, in the rotary soot blower, the blowing tube/element of the blower remains in the industrial boiler at all times. This tube is often equipped with multiple nozzles and rotates to clean a large portion of the industrial boiler. Since this soot blower doesn’t retract, the blowers cannot be used in the high-temperature areas of your boiler. Rotary soot blowers are ideal for use in the superheater, economizer, and air heater.

TESTIMONIALS

SEE WHAT OUR CUSTOMERS ARE SAYING

Benefits of Diamond Power Soot Blowers

- Improves operational efficiency

- Industrial Boilers last longer

- Keeps boiler running smoothly, safely, and efficiently

- Reduces the cost of thermal heat loss

- Reduces the need for maintenance

By using Diamond Power soot blowers, you’re not just maintaining your equipment — you’re investing in your facility’s long-term success and safety.

With over two decades of experience, Industrial Boilers America has been at the forefront of designing, deploying, and manufacturing top-tier industrial equipment for boilers and power plants. We understand that every facility faces unique challenges, so we’re committed to working closely with you to tackle your specific issues and goals. Our team excels in reverse engineering solutions that are precisely tailored to your application and needs.

We take the worry off your shoulders so you can focus on what truly matters — reinvest your time and resources into your business and community. Together, we can make a meaningful impact on global sustainability, ensuring a brighter future for everyone. At Industrial Boilers America, we’re more than just a provider; we’re your partner in creating solutions that drive success and positive change.

Better Solutions

REQUEST A QUOTE

Better Solutions

REQUEST A QUOTE

frequently asked questions

A Diamond Power soot blower is a high-performance boiler cleaning device manufactured by Babcock & Wilcox (B&W). It utilizes steam, compressed air, or water to remove soot and ash buildup inside industrial boilers, thereby maintaining efficiency and ensuring safety.

These soot blowers extend a lance or nozzle into the boiler. High-pressure steam, air, or water is forced through the nozzle to dislodge soot deposits from boiler surfaces. Once dislodged, the soot is carried away by flue gas to the dust collection or the stack.

Diamond Power offers several configurations to suit different boiler sections and cleaning needs:

- Retractable/long retractable (LRSB) blowers

- Wall / fixed blowers

- Rotary blowers (fixed, rotating nozzles)

- Air heater blowers (for cold-end/low-temperature sections)

- Proven reliability & brand trust, broad configurations & flexibility to adapt to different boiler layouts, pressures, and cleaning needs

- High-quality materials

- The capability to integrate intelligent control systems (e.g. Titanium or PowerClean) for optimized cleaning

Consider these factors:

- Boiler section (superheater, economizer, air heater, etc.)

- Cleaning area size and reach requirements

- Operating temperature, pressure, and the blowing medium available

- Ease of maintenance and access constraints

- The ability to integrate controls and optimization systems

If you’re unsure, our team can help you specify the optimal model for your system.